13 Unique Dial Indicators How To Use Free

13 Undercover Dial Indicators How To Use - Dial indicators are used to align a workpiece in a machine. In terms of various components of a dial indicator, it is made by pinions, levers as well as gears.

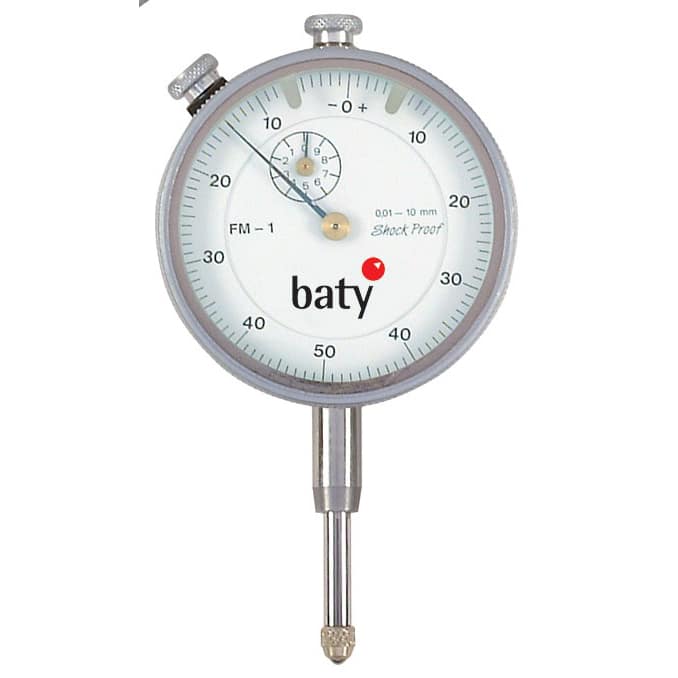

Hot Rod Engine Tech How to Use a Dial Indicator Hot Rod . The primary parts of a dial indicator are the face or dial, the case, and the plunger.

Dial indicators how to use

13 Absolute Dial Indicators How To Use. Dial indicators are used in enormous ways by engineers, some of them are given below briefly: Accurate use of a dial indicator requires rigid mounting and absolute stability. Hence dial indicators are almost always used with Dial indicators how to use

Dial indicators are mostly used in engine building. How you position the probe will directly relate to how accurate your measurements will be. Sometimes you will see dial indicators used to help determine machine and equipment tolerances. Dial indicators how to use

The dial indicator has been around since the early 1900s. Dial indicators are used primarily for measuring gauges and fixtures. But the sector type dial indicators are not useful for measuring any tool or workpiece. Dial indicators how to use

It is indicated on the face of the dial by a dial finger. Dial indicators typically measure ranges from 0.25 mm to 300 mm (0.015in to 12.0in), with graduations of 0.001 mm to 0.01 mm (metric) or 0.00005in to 0.001in (imperial/customary). This shape gives point contact, allowing for consistent measurements as the tip moves through its arc (via consistent offset distance from ball surface to center point, regardless of ball contact angle with the measured surface). Dial indicators how to use

Dial indicator alignment basics dial indicators are measuring devices designed expressly to measure relative position. Dial indicators are classified as dial gauges, where reading is done with the use of a clock, and digital gauges, where reading is done directly on an electronic digital indication, depending on the reading system. Alternatively, the dial test indicator is most often used for surface plate layout work or indicating measurements during machine setup. Dial indicators how to use

As an example, engineers often use two types of dial indicators such as sector shape and circular shape. But most often we don’t know how to use it correctly. Several things on how to use dial indicator such as the angle position of plunger and surface, employing the holder, zeroing the reading, etc one thing you have to always keep in mind when using a dial indicator is the angle that it shapes to the surface must be 90. Dial indicators how to use

The word “test” is also an easy way to always choose the right indicator. The plunger is a spring loaded part that can be depressed into the case causing the dial to move clockwise. Take a look at wha. Dial indicators how to use

Often, they are just called test indicators. Here’s how to select the right one for a given application. It is often used by engineers to Dial indicators how to use

Primarily dial indicators will measure the distance between two surfaces. How do you use dial indicator to align shafts? Dial test indicators, whose tips swing in an arc rather than plunging linearly, usually have spherical tips. Dial indicators how to use

Among the different types, the ones with the dial indicators are quite popular. Dial indicators consists of a body with a round graduated dial and a contact point connected with a spiral. As opposed to plunger dials, lever dials are used more often due to their compactness and overall ease of use. Dial indicators how to use

They can be used to measure crankshaft thrust, deck clearance, and other things. Dial indicators are a must have for most shops. If the indicator moves all while the measurement is being taken, the measurement is compromised. Dial indicators how to use

Dial indicators can be defined as the small measuring instrument that can be used in several mechanical means to measure a certain deviation of a mechanical component. How do you use a dial indicator? Lever dial indicators these dials have a level and scroll mechanism. Dial indicators how to use

Such as, in the case of edm, grinding machine, lathe machine, and milling machine. They are also an essential machinist tool. As a result, we end up getting the wrong measurement and stop using the device. Dial indicators how to use

It operates on the principle, that a very slight upward pressure on the spindle at the contact point is multiplied through a system of gears and levers. Dial indicators how to use

Hot Rod Engine Tech How to Use a Dial Indicator Hot Rod . It operates on the principle, that a very slight upward pressure on the spindle at the contact point is multiplied through a system of gears and levers.

Hot Rod Engine Tech How to Use a Dial Indicator Hot Rod . It operates on the principle, that a very slight upward pressure on the spindle at the contact point is multiplied through a system of gears and levers.

Dial indicators and dial test indicators with a minilathe . As a result, we end up getting the wrong measurement and stop using the device.

Using Dial Indicators to Get More Accurate Measurements . They are also an essential machinist tool.

Using Dial Indicators to Get More Accurate Measurements . They are also an essential machinist tool.

How to Read a Dial Indicator Sciencing . Such as, in the case of edm, grinding machine, lathe machine, and milling machine.

How to Read a Dial Indicator Sciencing . Such as, in the case of edm, grinding machine, lathe machine, and milling machine.

Lot of Misc. Dial Indicators *See Photos* BTM Industrial . How do you use a dial indicator?

Lot of Misc. Dial Indicators *See Photos* BTM Industrial . How do you use a dial indicator?

0.01mm/0.0005" Range 0 24.5mm/1" Gauge Digital Dial . Dial indicators can be defined as the small measuring instrument that can be used in several mechanical means to measure a certain deviation of a mechanical component.

0.01mm/0.0005" Range 0 24.5mm/1" Gauge Digital Dial . Dial indicators can be defined as the small measuring instrument that can be used in several mechanical means to measure a certain deviation of a mechanical component.

Dial Indicators & Dial Indicator Calibration Rhopoint . If the indicator moves all while the measurement is being taken, the measurement is compromised.

Dial Indicators & Dial Indicator Calibration Rhopoint . If the indicator moves all while the measurement is being taken, the measurement is compromised.

Precision Measuring For The AtHome Mechanic DIY Moto Fix . Dial indicators are a must have for most shops.